**Material Selection Guide: Choosing the Right Automotive Hose & Fitting Materials**

In the demanding environment of modern automotive systems, selecting the optimal material for engine tubing is critical to ensure performance durability, and cost-efficiency. As a leading manufacturer of rubber hoses, steel pipes, and hydraulic assembly fittings, we break down the key factors to consider when sourcing engine tubing components:

Temperature & Pressure Resistance

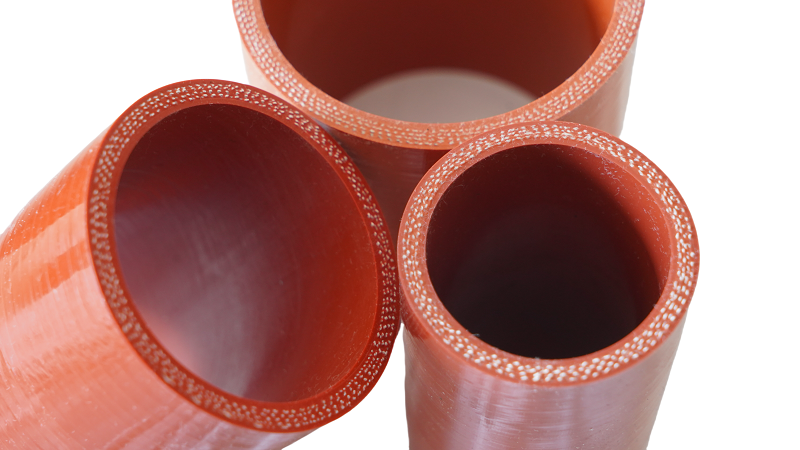

• Silicone & EPDM Rubber Hoses: Ideal for coolant lines and low-pressure fuel systems (-50°C to +200°C).

• Stainless Steel Tubes: Withstand extreme heat (up to 800°C) in turbocharger systems and exhaust manifolds.

![]()

Scenario-Based Recommendations:

⚙️ Turbocharger Systems: 304 stainless steel pipes with heat-resistant coatings

⚡ EV Battery Cooling: Silicone hoses

��️ Fuel Delivery: Multi-layer nylon/fluoroelastomer lines with AN fittings

Why Partner With Us?

• Material Science Expertise:30+ years of experience in automobile parts manufacturing

• Custom Engineering: Customize pipe fittings size, performance and special materials according to your needs

• Global Certifications: IATF 16949 approvals

• Full-System Support: From raw tubing to pre-assembled kits with leak-test validation

[Contact US] to analyze your application requirements and receive material test reports.