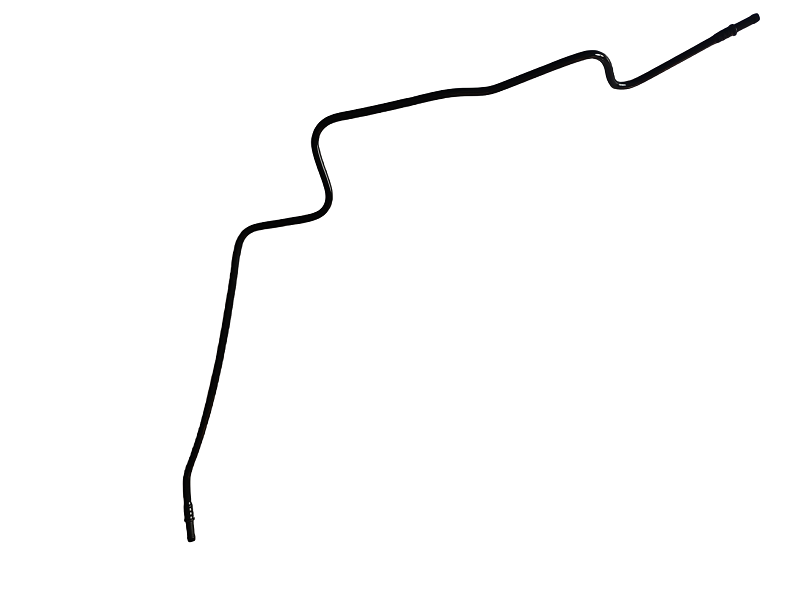

Automobile nylon fuel pipe

Automobile fuel pipe in terms of material, nylon has excellent corrosion resistance, can effectively resist the erosion of chemical substances in fuel, and greatly extend its service life. Automobile fuel pipe in terms of performance, its light material helps the car achieve lightweight goals and reduce the weight of the whole vehicle, thereby significantly improving fuel economy and reducing energy consumption. In terms of structural design, nylon fuel pipes are often compounded with other materials to achieve complementary advantages, further enhance overall performance, and provide solid support for the safe and stable operation of the automobile fuel supply system in all aspects, becoming a reliable guarantee for the power output of the vehicle.

As the precision-engineered vascular system of modern powertrains, Automobile Fuel Pipe solutions crafted from advanced nylon composites redefine fuel transfer efficiency. These Tubes for Nylon Fuel Pipe leverage PA12-based material science to achieve 60% weight reduction versus traditional metal lines while maintaining 25Bar burst strength – a perfect synergy of lightness and rugged reliability.

The Automobile Fuel Pipe’s molecular structure resists ethanol blends, biodiesel corrosion, and hydrocarbon permeation with 0.03g/m²/24h emission rates. As critical Tubes for Nylon Fuel Pipe, their smooth internal bore minimizes turbulent flow, ensuring 98% volumetric delivery accuracy even during aggressive acceleration cycles.

Innovative architecture empowers these components:

Multi-layer construction combines chemical-resistant inner lining with anti-static outer shielding

Memory-flex technology allows tight-radius bends without flow restriction

From compact hybrids to heavy-duty diesel platforms, the Automobile Fuel Pipe excels as next-gen Tubes for Nylon Fuel Pipe. Their thermal resilience spans -40°C cold starts to 125°C engine bay temperatures, preventing brittle fractures or deformation across extreme operating cycles.

As sustainable Tubes for Nylon Fuel Pipe, these lines support circular economy goals through 92% recyclable material content. Their vibration-damping properties neutralize 20-200Hz engine harmonics, protecting sensitive fuel injectors from pulsation-induced wear.

By optimizing fluid dynamics and material durability, these Tubes for Nylon Fuel Pipe enhance fuel system responsiveness while reducing parasitic energy losses. Their precision-molded connectors eliminate galvanic corrosion risks at junction points, ensuring decade-long service life without degradation.

Whether in stop-and-go urban traffic or cross-continental hauling, the Automobile Fuel Pipe maintains consistent pressure delivery. The Tubes for Nylon Fuel Pipe’s silent operation – achieved through dampened fluid resonance – contributes to premium cabin acoustics, while their crash-optimized design prevents post-impact fuel leakage.

From motorsport applications demanding millisecond response times to autonomous vehicles requiring faultless reliability, this nylon-based Automobile Fuel Pipe system stands as the invisible guardian of combustion efficiency – enabling cleaner emissions, maximized mileage, and uncompromised safety across every kilometer.

According to customer needs, our company provides personalized customization services, including performance, size, appearance, etc., and wins the favor of consumers with high quality and high service.