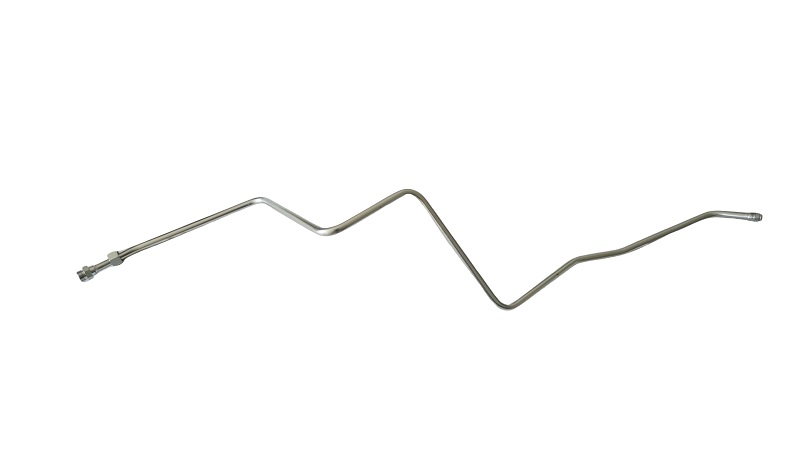

Oil And Gas Separator Air Pipe Steel Pipe Assembly

The stainless steel air pipe assembly of the oil-gas separator is full of highlights. The stainless steel material used is far more corrosion-resistant than ordinary materials. It can effectively resist erosion in the complex chemical environment of oil and gas, greatly extend the service life and reduce maintenance costs. The excellent high-temperature resistance can work stably in the high-temperature environment of the engine compartment to ensure that the oil and gas transmission is not affected by temperature. From the perspective of structural design, the oil and gas separator outlet pipe assembly diameter and shape are precisely calculated to optimize the oil and gas flow path, improve separation efficiency and reduce energy loss.

Oil-Gas Separator Air Pipe Assembly: Precision Engineering for Engine Protection

The Oil-Gas Separator Intake Pipe Assembly and Oil and Gas Separator Outlet Pipe Assembly form a critical subsystem in modern engine management, working synergistically as the Oil and Gas Separator Air Pipe Assembly to maintain optimal crankcase ventilation and lubrication integrity. These precision-engineered stainless steel components ensure efficient oil-gas separation while balancing internal pressures, directly contributing to extended engine life and reduced environmental impact.

Core Functions & Design

Intake System

Oil-Gas Separator Intake Pipe Assembly:

Guides crankcase blow-by gases into the separator at 15-25 m/s flow rates

304 stainless steel construction resists acidic gas corrosion (pH 3-9)

Internal baffle design pre-separates 40-60% oil droplets

Separation Process

Centrifugal forces achieve 98%+ oil separation efficiency

Maintains oil viscosity within SAE 5W-30 specifications

Outlet Management

Oil and Gas Separator Outlet Pipe Assembly:

Returns purified oil via 8-12mm diameter return lines

Directs cleaned gases to intake manifold/atmosphere

Pressure-balanced design (±0.02 bar)

Material & Manufacturing

The Oil and Gas Separator Air Pipe Assembly utilizes:

Laser-welded 0.8-1.2mm 316Ti stainless steel

Argon-arc welded joints (ASME Section IX certified)

Performance Advantages

Reduces oil consumption by 60-80%

Maintains crankcase vacuum within 0.5-1.5 kPa

Withstands 500,000+ thermal cycles

Customization Options

The Oil-Gas Separator Intake Pipe Assembly and Outlet Pipe Assembly support tailored configurations:

Diameter variations: 25-100mm

Orientation: 0°-90° bend angles

Industry Applications

This Oil and Gas Separator Air Pipe Assembly proves essential in:

Heavy-duty diesel engines

Hybrid powertrains with stop-start systems

Marine engines

Racing engines requiring rapid pressure equalization

From passenger cars to industrial generators, oil separator inlet pipe assemblies and oil separator outlet pipe assemblies work together to protect engine components while meeting stringent emission regulations. As part of a complete oil separator air pipe assembly, their precision engineering ensures reliable performance under a variety of operating conditions, making them an important part of the automotive engine system and an integral part of the modern combustion management system.