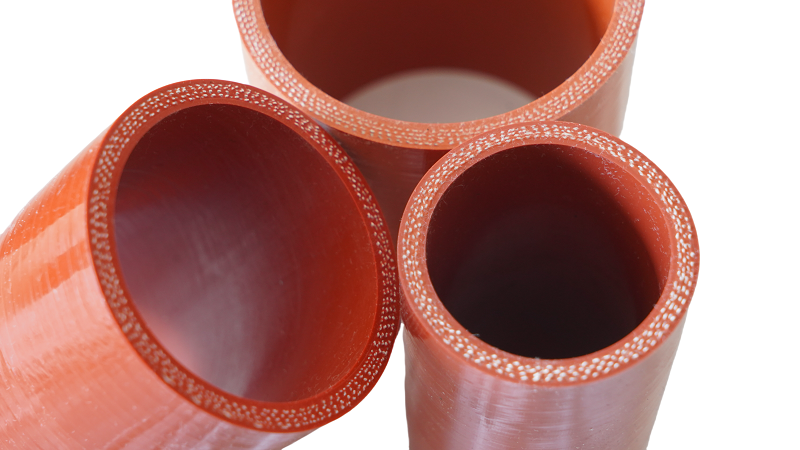

Aramid Fabric Reinforced Silicone Hose For Car

The aramid fiber sandwich consists of three parts: inner layer, reinforcement layer and outer layer:

The inner layer is generally a silicone layer, which can directly contact the gas, liquid and other media to be transported, ensuring that the media does not leak and is not affected by the hose material. The reinforcement layer is woven from aramid fiber, which has the characteristics of high strength, high modulus, low elongation, excellent high temperature resistance, good chemical corrosion resistance, fatigue resistance and dimensional stability. The outer layer is usually also a silicone layer, which mainly plays a protective role, with weather resistance, ozone resistance, wear resistance, etc., to prevent the reinforcement layer and the inner layer from being eroded and damaged by the external environment.

**Aramid Fabric Reinforced Silicone Hose For Car: Revolutionizing Automotive Fluid Management**

The **Aramid Fabric Reinforced Silicone Hose For Car** stands as a pinnacle of engineering for modern vehicle systems, combining the unparalleled strength of aramid fibers with the thermal resilience of silicone. Designed to excel in extreme environments, this **Aramid Fiber Pipe For Car** is engineered to meet the rigorous demands of high-performance automotive applications, from turbocharged engines to advanced thermal management systems.

**Unmatched Technical Superiority**

- **Material Synergy**: The hose’s core comprises high-purity silicone, reinforced with cross-woven aramid fabric layers. Aramid fibers, known for their tensile strength (5× stronger than steel by weight), provide exceptional burst pressure resistance (up to 15 bar), while the silicone matrix ensures flexibility across a temperature range of -60°C to +230°C.

- **Chemical Compatibility**: Resists degradation from ethanol blends, biodiesel, and aggressive engine oils .

**Critical Automotive Applications**

1. **Turbocharger Systems**: As an **Aramid Fiber Pipe For Car**, it handles 2.5 bar boost pressures without deformation, maintaining laminar airflow for optimal turbo efficiency.

2. **Coolant Circulation**: Aramid fiber Pipe for car low thermal conductivity minimizes heat transfer to engine bays, protecting sensitive electronics.

3. **Emission Control**: UV-resistant outer layers (ASTM D7508) prevent ozone cracking in exhaust gas recirculation (EGR) systems.

**Precision Manufacturing**

Each **Aramid Fabric Reinforced Silicone Hose** undergoes:

- **Aramid Weaving**: 45° bias-angle fabric alignment for uniform stress distribution.

- **Multi-Step Vulcanization**: Ensures complete silicone-to-fabric adhesion.

- **Laser-Validated Geometry**: Precision-cut ends with ±0.2 mm tolerance for leak-proof connections.

Tested to ISO 11425 and OEM standards, this **Aramid Fiber Pipe For Car** exceeds 500-hour salt spray resistance and demonstrates <0.1% gas permeation under SAE J30 R10 testing. Aramid fiber pipe for car lightweight design (30% lighter than steel-braided alternatives) contributes to fuel efficiency without compromising durability.

In summary, the Aramid Fabric Reinforced Silicone Hose For Car redefines fluid system reliability. By integrating aerospace-grade materials with automotive-grade precision, it delivers unmatched performance in pressure retention, thermal stability, and chemical resistance—essential for next-generation vehicles navigating stringent emissions and efficiency standards.