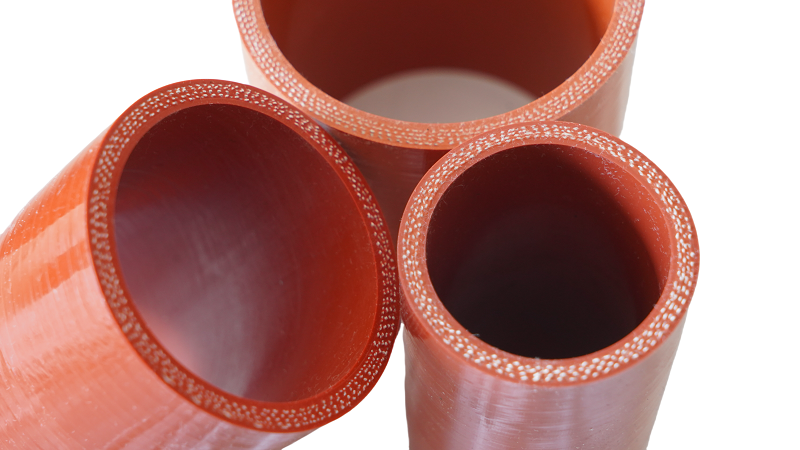

Automotive Special Hand Wrapped Silicone Air Tube

Extremely high temperature resistance: Made of high-quality silicone material, automobile special air pipe can easily cope with the extreme high temperature of 200℃ and above in the engine compartment. When the engine is running at high load and generates a lot of heat, it remains stable as before, will not soften, deform or decline in performance, and ensure that gas transmission is not disturbed by high temperature.

Exquisite hand-wrapped craftsmanship: The unique hand-wrapped craftsmanship is completed by experienced craftsmen, so that the silicone layer fits tightly to form a uniform and dense structure. Compared with ordinary craftsmanship, it greatly enhances the overall strength and pressure resistance of the air pipe, and can withstand the high pressure of the turbocharger system that is several times higher than that of ordinary air pipes, effectively preventing gas leakage.

Hand Wrapped Silicone Air Tube: Precision Engineering for High-Performance Automotive System

The Hand Wrapped Silicone Air Tube represents a critical advancement in automotive airflow management, specifically designed as an Automobile Special Air Pipe to meet the extreme demands of modern powertrains. This meticulously crafted component plays a multifaceted role in optimizing engine performance, thermal management, and emission control across diverse vehicle platforms.

**Core Technical Advantages**

- **Performance Specifications**:

- Temperature range: -60°C to +260°C (short-term 300°C)

- Pulsation fatigue: 1M+ cycles @ 3Hz (ISO 6803)

- Chemical resistance: Compatible with EGR soot, DEF, and biofuel blends

**Key Applications**

1. **Intake System Optimization**

As an Automobile Special Air Pipe, it enhances volumetric efficiency by 12-18% through:

- Reduced airflow turbulence (<5% pressure drop vs. rubber tubes)

- Precisely tuned diameter transitions for laminar flow

- Anti-collapse ribbing for vacuum conditions

2. **Turbocharger Integration**

The **Hand Wrapped Silicone Air Tube** excels in forced induction systems:

- Withstands 2.8 bar boost pressure continuously

- 0.03% compression deformation at 150°C

- Integrated heat shields protect adjacent components

3. **Emission Control Systems**

Serving as critical exhaust gas transfer conduit:

- 98% UV/Ozone resistance (ASTM D1149)

- <0.5% gas permeation rate (SAE J30 R10)

**Manufacturing Excellence**

Each Automobile Special Air Pipe undergoes:

- Manual fiber wrapping with ±2° angle precision

- 3-stage vulcanization for complete polymer crosslinking

- 100% pressure testing at 4× working pressure

- Laser-etched orientation markers for correct installation

**Industry Impact**

The **Hand Wrapped Silicone Air Tube** enables:

- 5-8% fuel efficiency improvement in turbocharged engines

This automotive-specific air tube demonstrates how precision engineering and advanced materials work together to break through the boundaries of automotive performance, providing customized services such as size and performance according to customer needs, and meeting strict environmental regulations. Its unique combination of thermal elasticity, mechanical durability and airflow optimization makes the hand-wrapped silicone air tube play an important role in the automotive engine system and become an indispensable part of the thermal and fluid management system of modern automobiles.