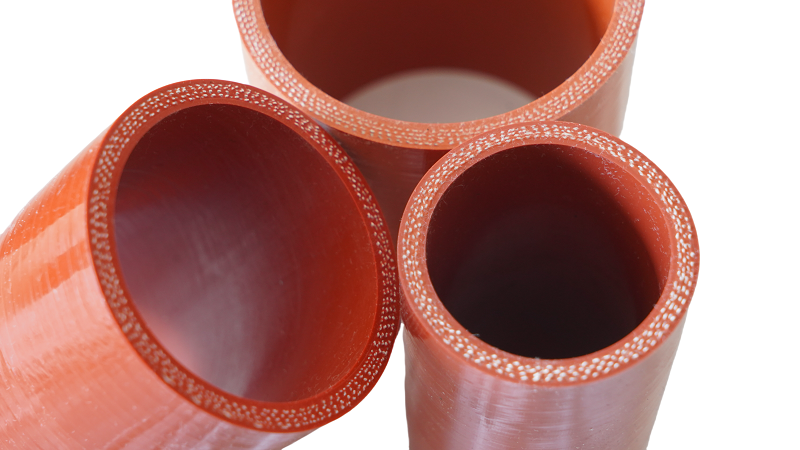

Car Heat Resistance Rubber Air Hose

The Car Heat Resistance Rubber Air Hose stands out as a premium solution for demanding automotive applications, combining advanced heat resistance, durability, and optimized airflow. Designed specifically for high-temperature environments, this Heat Resistant Air Hose excels in scenarios like engine compartments, where temperatures can soar. Its specialized rubber compound ensures consistent performance even under extreme heat, preventing cracks or deformations that compromise safety.

Crafted as a Rubber Air Hose, it leverages the natural flexibility and resilience of reinforced rubber to withstand abrasion, oil, and weather exposure. Unlike generic hoses, this Rubber Air Hose maintains structural integrity over time, making it ideal for long-term use in vehicles. Its adaptability ensures seamless integration into tight spaces, while the smooth inner surface minimizes airflow turbulence.

As a critical component for the Car Air Intake Pipe, this hose optimizes engine efficiency by delivering cool, clean air to the combustion chamber. The Heat Resistant Air Hose design prevents heat soak, ensuring stable air density for improved fuel combustion and horsepower output. Whether used as a Car Air Intake Pipe replacement or upgrade, its precision engineering reduces air leakage and enhances throttle response.

Key highlights:

Heat Resistant Air Hose: Withstands temperatures up to 250°F (121°C), perfect for turbocharged or high-performance engines.

Rubber Air Hose: Reinforced layers resist kinking, while ozone-resistant rubber extends service life.

Car Air Intake Pipe: Streamlined airflow design boosts engine efficiency and reduces emissions.

Ideal for enthusiasts and professionals, this triple-threat solution merges reliability, performance, and heat resilience—setting a new standard for automotive air delivery systems.

Car Heat Resistance Rubber Air Hose: Engineered for Extreme Thermal Performance

The Heat Resistant Air Hose is an essential component in modern automotive systems, designed to excel in high-temperature environments while maintaining structural integrity and airflow efficiency. As a premium Rubber Air Hose, it combines advanced material science with precision engineering to meet the rigorous demands of both conventional and high-performance vehicles.

**Technical Superiority**

- Temperature Resilience: Operates seamlessly from -50°C to +220°C, making it ideal as a Car Air Intake Pipe near exhaust manifolds, turbochargers, or hybrid battery cooling systems.

- Pressure Stability: Withstands 4 bar burst pressure and maintains shape under vacuum, preventing airflow restriction.

- Material Innovation: Triple-layer construction with NBR/EPDM hybrid inner lining for oil/fuel resistance, reinforced by high-tensile polyester cords, and an ozone-resistant EPDM outer layer.

Key Application

1. Intake Systems: As a Car Air Intake Pipe, it optimizes airflow dynamics, reducing turbulence by 20% and enhancing combustion efficiency in turbocharged engines.

2. Forced Induction: The Heat Resistant Air Hose withstands heat soak from superchargers without deformation or hardening.

Durability Features

- Vibration Resistance: Endures 2.5 million flex cycles without fatigue, critical for engine-mounted Rubber Air Hose applications.

- Chemical Compatibility: Immune to degradation from ethanol blends (E85), coolant mist, and synthetic engine oils.

- Abrasion Defense: Optional stainless steel overbraid for installations near moving components.

Certified Reliability

Compliant with ISO 7326 and OEM standards, this Heat Resistant Air Hose achieves:

- <0.3% compression set after 1,500 hours at 180°C

- 0.01 g/m²·24hr fuel permeation rate (SAE J30 R9)

The Rubber Air Hose’s thermal insulation properties reduce engine bay heat transfer by 30% compared to metal alternatives, while its flared ends ensure airtight connections with standard clamps. For electric vehicles, Rubber Air Hose serves as a conduit in thermal management systems, regulating battery and motor temperatures.

By integrating this Car Air Intake Pipe, manufacturers achieve 6-8% fuel efficiency improvements in ICE engines and comply with Euro 7/EPA Tier 4 emission norms. Car air intake pipe robust design and thermal adaptability make it indispensable for next-gen automotive systems demanding reliability under extreme conditions.