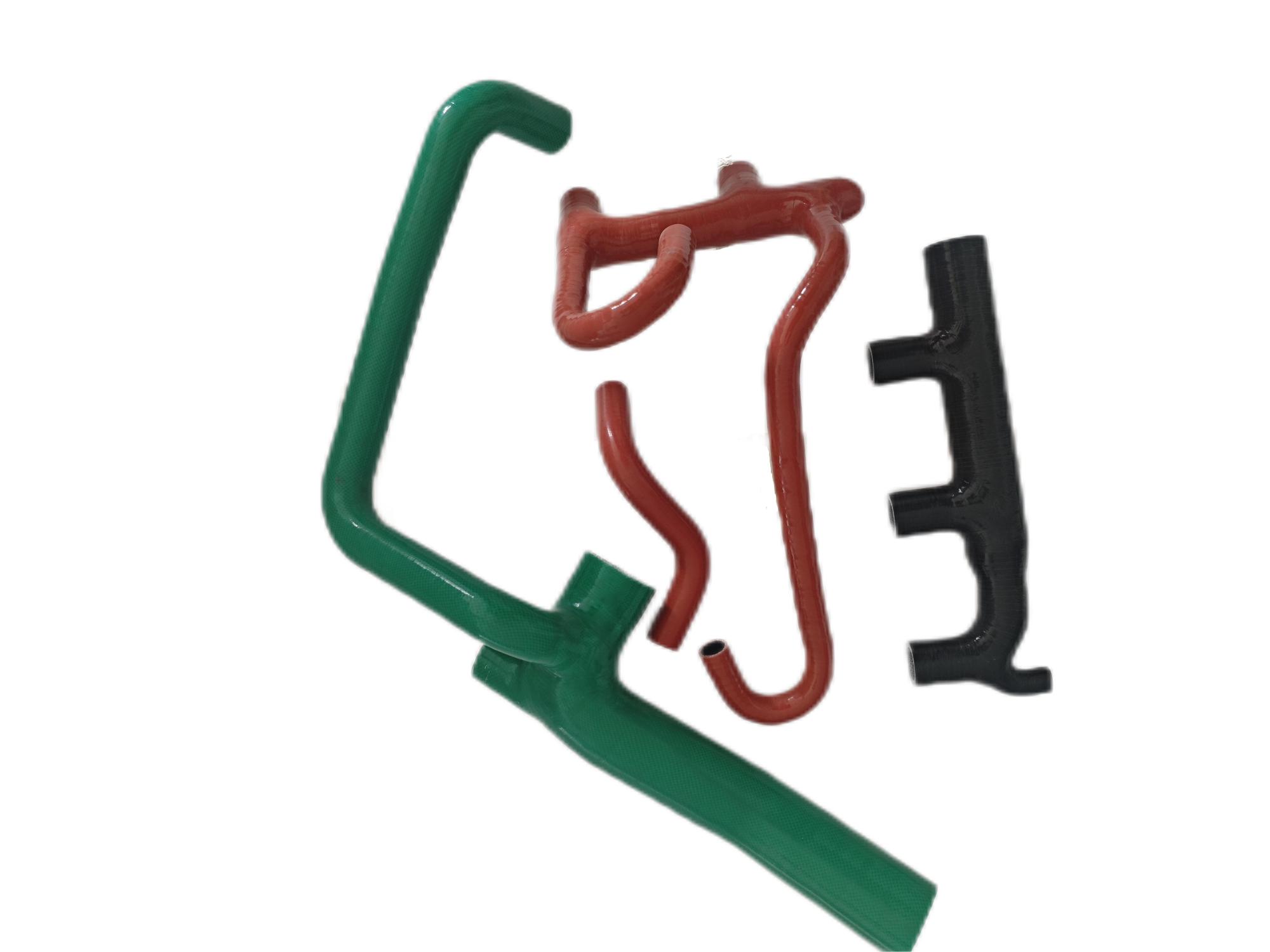

Flexiable EPDM Rubber Water Hose

Extraordinary materials create excellent quality: EPDM is used, and its saturated main chain structure gives the water pipe excellent chemical stability, which can easily resist corrosion from water, acid, alkali and other chemical substances. The large number of side methyl groups on the molecular chain improves flexibility and elasticity, ensuring the performance of the water pipe from the root of the material.

Adapt to temperature and maintain stable performance: It can work stably in the extreme temperature range of -50℃ to 150℃. It does not harden or crack at low temperatures, and still maintains good flexibility and pressure bearing capacity; it does not soften or deform at high temperatures, and continuously and stably transports various media without fear of changes in ambient temperature.

Flexible EPDM Water Pipe: The Backbone of Automotive Thermal Management Systems

The Flexible EPDM Water Pipe, a premium-grade Car Rubber Hose, is integral to modern automotive thermal regulation systems. Engineered from ethylene propylene diene monomer (EPDM) rubber, this car rubber hose excels in both engine cooling and air-conditioning applications, delivering unmatched durability and performance. In engine cooling systems, the Flexible EPDM Water Pipe seamlessly connects radiators, water pumps, and engine cylinders, forming a closed-loop circuit that efficiently circulates coolant. By absorbing and dissipating heat generated during combustion, car rubber hose ensures the engine operates within an optimal temperature range (typically 85–100°C), preventing overheating, component warping, or catastrophic engine failure. Its exceptional heat resistance allows it to withstand continuous exposure to temperatures up to 150°C, while its low-temperature flexibility (-40°C) ensures reliable performance in frigid climates, eliminating risks of cracking or hardening.

As a versatile Car Rubber Hose, its applications extend to automotive air-conditioning systems, where it transports refrigerants like R134a or R1234yf. The car rubber hose’s airtight construction and chemical inertness prevent refrigerant leakage, ensuring consistent cooling efficiency and compliance with stringent environmental regulations. Reinforced with polyester or aramid fiber layers, the Flexible EPDM Water Pipe resists pressure fluctuations, vibration stresses, and abrasion, even in high-engine-bay turbulence. Its smooth inner lining minimizes flow resistance, enhancing coolant circulation rates by up to 20% compared to conventional hoses.

The Car Rubber Hose leverages EPDM’s inherent advantages: ozone resistance, UV stability, and immunity to coolant additives like ethylene glycol or corrosion inhibitors. These properties prevent swelling, degradation, or premature aging, extending service intervals to over 100,000 miles. Automotive manufacturers prioritize this hose for its compatibility with hybrid and electric vehicles, where thermal management precision is critical for battery efficiency.

Advanced versions of the Flexible EPDM Water Pipe integrate smart monitoring features, such as embedded sensors that detect coolant pH levels or micro-leaks, transmitting real-time data to the vehicle’s ECU for proactive maintenance alerts. This innovation aligns with the automotive industry’s shift toward predictive diagnostics and sustainability.

The Car Rubber Hose ensures leak-proof connections through precision-molded fittings and corrosion-resistant clamps. Its lightweight design reduces overall vehicle mass, contributing to fuel efficiency and lower emissions.

In summary, the Flexible EPDM Water Pipe redefines reliability in automotive thermal systems. As a high-performance Car Rubber Hose, it combines thermal resilience, chemical durability, and mechanical adaptability, making it indispensable for modern vehicles. By integrating this component, automakers enhance engine longevity, optimize climate control, and deliver superior driving experiences.