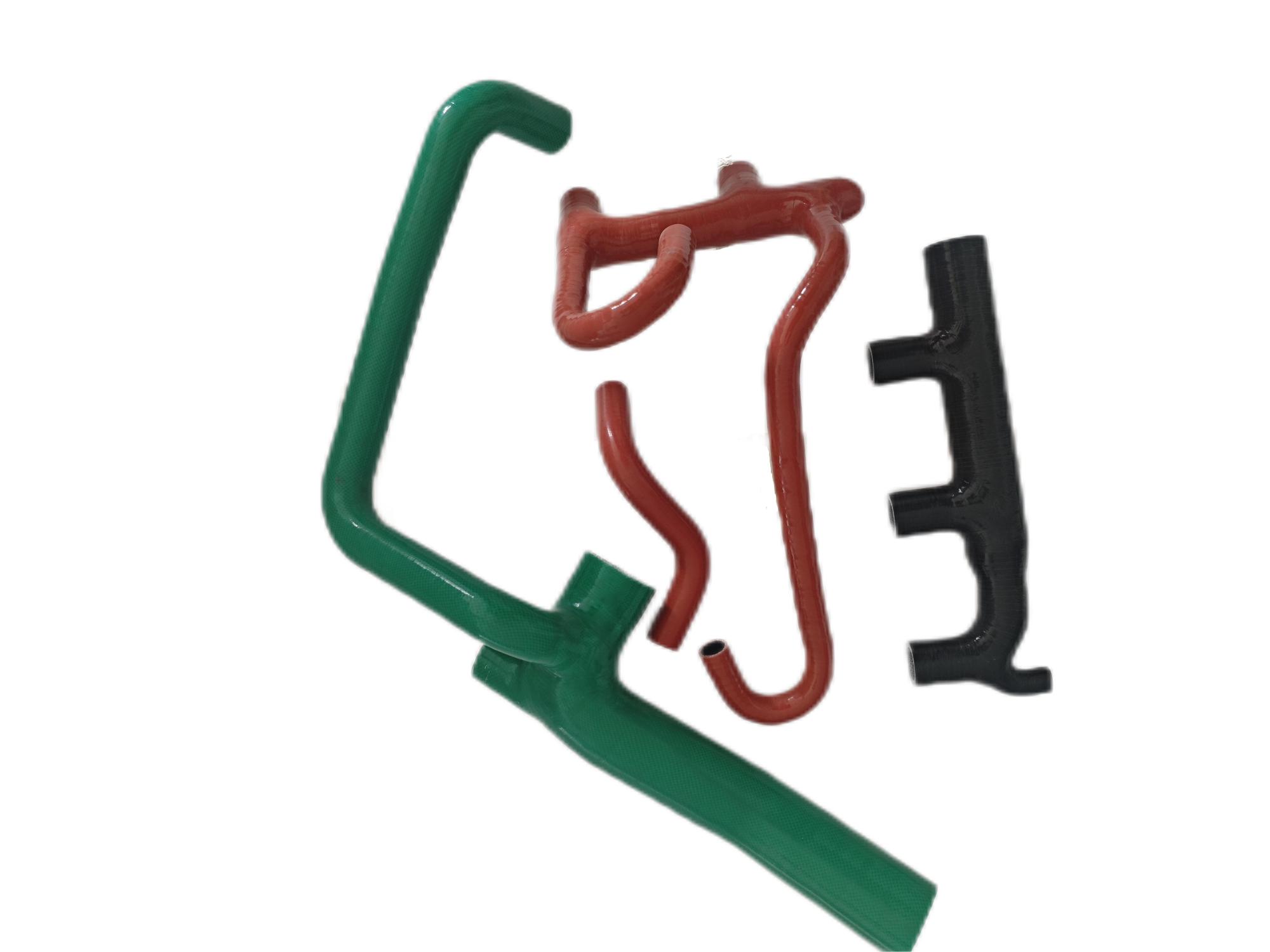

Radiator Rubber Overflow Pipe For Automative

Flexible installation and strong adaptability: With good flexibility, it can easily adapt to the complex and compact space layout in the engine compartment. Whether it is a narrow gap or an irregular corner, it can be flexibly bent to the required shape to achieve precise installation, overcome the problem of space limitations in the engine compartment of various models, ensure close connection with the radiator and overflow tank, and ensure smooth coolant transmission.

Excellent performance, stable operation: With excellent temperature and pressure resistance, it can withstand the high temperature generated when the engine is working and the pressure fluctuations during the coolant circulation process, ensuring that it will not soften or break under extreme working conditions. At the same time, the tube wall structure is tight and the sealing performance is excellent, which effectively prevents coolant leakage, prevents coolant loss and corrosion to surrounding components, and provides a solid guarantee for the stable operation of the automobile cooling system.

The Radiator Overflow Pipe Automotive system, particularly the Automobile Rubber Hose, serves as an unsung hero in maintaining the efficiency and longevity of a vehicle's engine. As a critical component of the cooling system, this specialized hose performs dual functions that are essential for thermal management under dynamic operating conditions.

When the engine generates heat during combustion or prolonged operation, the coolant expands volumetrically due to thermal dynamics. Without a properly functioning Radiator Overflow Pipe Automotive, this pressure buildup could exceed the radiator's structural limits, leading to cracks, leaks, or even catastrophic failure. Here, the Automobile Rubber Hose acts as a pressure-regulated conduit, channeling excess coolant to the overflow tank. Automobile rubber hose flexible yet durable construction, often made from ethylene propylene diene monomer (EPDM) rubber, ensures resistance to extreme temperatures (-40°C to +150°C) and chemical degradation from antifreeze mixtures. This material science innovation allows the hose to maintain elasticity and sealing integrity even after years of thermal cycling.

Conversely, when the engine cools down, the contracted coolant creates a vacuum within the radiator. The Automobile Rubber Hose facilitates reverse flow, drawing stored coolant back from the overflow tank to replenish the system. This bidirectional functionality ensures consistent coolant volume, preventing air pockets that could disrupt heat transfer efficiency. The Radiator Overflow Pipe Automotive thus acts as a dynamic equilibrium manager, adapting to temperature fluctuations while maintaining optimal fluid levels for uninterrupted circulation.

The design specificsof the Automobile Rubber Hose further enhance its reliability. Reinforced with nylon braiding or polyester cord, it resists kinking and abrasion caused by engine vibrations or contact with adjacent components. Its clamp-compatible ends ensure leak-proof connections to both the radiator neck and overflow tank, critical for sustaining pressure differentials. Modern variants even incorporate sensor-friendly materials to integrate with electronic cooling system monitors.

Neglecting this component can have cascading consequences. A cracked or hardened Radiator Overflow Pipe Automotive may lead to coolant loss, resulting in overheating scenarios that warp cylinder heads or damage piston rings. Conversely, a collapsed hose during cooldown phases can starve the engine of coolant, causing uneven thermal stresses. Regular inspections for swelling, brittleness, or mineralization deposits are therefore imperative during routine maintenance.

In hybrid and electric vehicles, the Automobile Rubber Hose takes on added significance. While internal combustion engines dominate thermal loads, battery thermal management systems increasingly rely on similar overflow mechanisms to regulate coolant flow for lithium-ion packs. This expands the application scope of Radiator Overflow Pipe Automotive technology beyond traditional powertrains.

Manufacturers continue to innovate hose architectures, with silicone-rubber hybrids and multi-layer constructions entering the market. These advancements aim to address emerging challenges like higher turbocharger temperatures and extended service intervals in modern engines.

In conclusion, the Radiator Overflow Pipe Automotive and its Automobile Rubber Hose embodiment represent a masterclass in fluid dynamics engineering. By harmonizing material resilience with precise hydraulic regulation, this component safeguards against thermal extremes, reduces maintenance costs, and ultimately contributes to lowering vehicular emissions through stabilized combustion temperatures. Its unassuming appearance belies its status as a cornerstone of automotive thermal management – a testament to how precision-engineered rubber components remain indispensable in an era of advancing automotive technology.