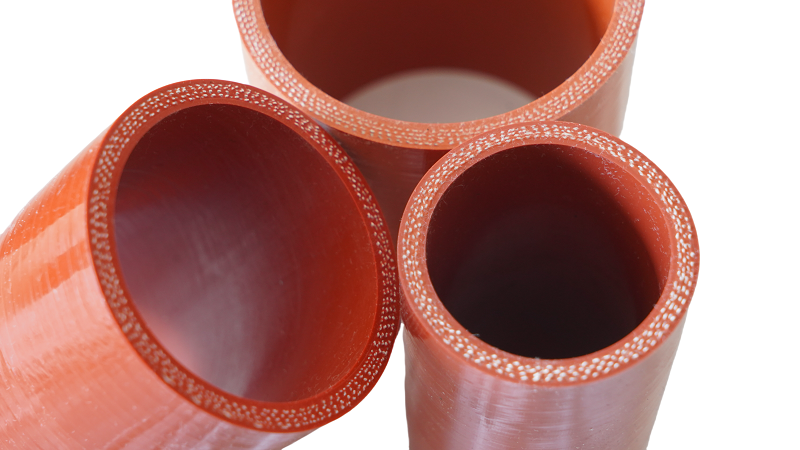

Oil And Gas Separator Rubber Air Pipe

Good flexibility: It can be easily bent and installed, adapt to different installation positions and spatial layouts, and can realize flexible connection between the oil-gas separator and other components in the limited engine compartment space.

High pressure resistance: The oil-gas separator will be subjected to a certain pressure during operation. The rubber air pipe needs to have sufficient pressure resistance to ensure that it will not break or leak under normal working pressure, and ensure the sealing and safety of the oil-gas separation system.

Anti-aging: In the harsh environment of high temperature, humidity, oil pollution, etc. in the engine compartment, the rubber air pipe needs to have good anti-aging performance, be able to work stably for a long time, and not prone to aging phenomena such as cracking, hardening, and softening, reducing the replacement frequency and maintenance costs.

Advanced Oil & Gas Separator Hose System: Precision Engineering for Modern Emission Control

In modern internal combustion systems, the Oil and Gas Separator Outlet Rubber Hose and Oil and Gas Separator Air Intake Rubber Hose form a critical duo for maintaining engine efficiency, emissions compliance, and component longevity. These specialized hoses address the complex challenges of crankcase ventilation by balancing oil mist recovery, pressure regulation, and chemical resistance across extreme operating conditions.

Oil and Gas Separator Outlet Rubber Hose: Pulsation Management & Vibration Absorption

Engineered for aggressive blow-by gas handling, the Oil and Gas Separator Outlet Rubber Hose integrates spiral-wound steel wire reinforcement within a tri-layer NBR/EPDM/FKM compound. The corrugated profile enables 15mm axial vibration displacement absorption, critical for protecting fragile separator membranes in high-RPM diesel applications.

Oil ad Gas Separator Air Intake Rubber Hose: Optimized Flow Dynamics

Complementing the outlet system, the Oil and Gas Separator Air Intake Rubber Hose employs smooth-wall EPDM construction with helical reinforcement to maintain crankcase pressure within ±0.5kPa. Its computational fluid dynamics (CFD)-optimized bore reduces airflow turbulence, achieving a 35% lower pressure drop versus ribbed competitors. The hose's thermal-stable formulation preserves elasticity from -40°C arctic cold starts to 150°C turbocharged environments, preventing microcracking that causes vacuum leaks.

Material Science Breakthroughs

Both the Oil and Gas Separator Outlet Rubber Hose and Oil and Gas Separator Air Intake Rubber Hose utilize adaptive compounding:

NBR Dominant (70% acrylonitrile): Resists swelling in biodiesel/sulphur-rich diesel particulate environments (15% better oil resistance vs. standard NBR)

EPDM Variants: Withstand 300% stretch recovery after -40°C thermal shocks in mining equipment

FKM Enhanced: 50% slower compression set formation in 180°C turbocharger-adjacent installation

Customization & Compatibility

Available in 12-50mm ID configurations, these hoses adapt to diverse platforms:

Outlet Hose: Features 304 stainless steel quick-clamps (VDA 6.3 certified) for 5-minute field replacement on hybrid bus engines

Intake Hose: Integrates molded anti-collapse rings for agricultural equipment experiencing 95% relative humidity

Memory-flex technology ensures both hoses retain OEM-specified routing geometry post-installation, eliminating stress points near EGR coolers.