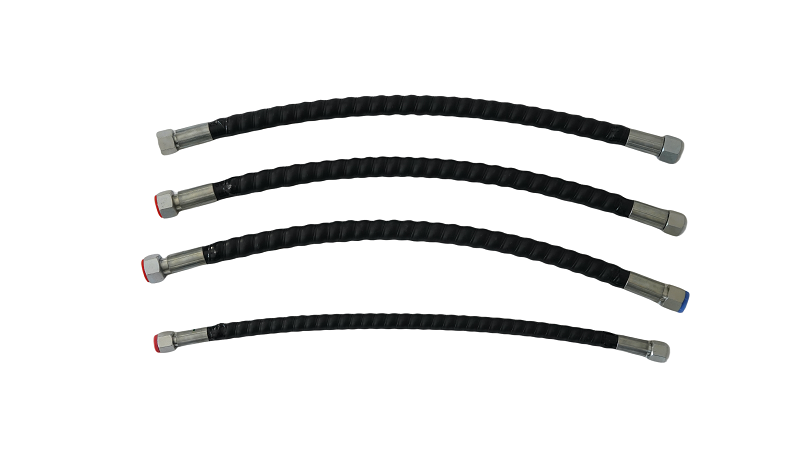

Anti-aging Automobile Coolant Hose Assembly

The material properties are excellent, the inner rubber layer is compatible with the coolant, it does not swell, harden or become brittle after long-term contact, and has stable physical properties; the fiber or steel wire of the reinforcement layer has high strength and toughness, and the structure is complete under complex stress; the special rubber of the outer protective layer has a stable chemical structure and reliable protective performance under various climatic conditions.

Premium Anti-aging Coolant Hose Assembly: Revolutionizing Engine Thermal Management

Engineered to redefine cooling system longevity, our Anti-aging Coolant Hose Assembly combines advanced polymer science with rigorous durability testing to deliver unparalleled performance in modern automotive applications. Designed for commercial fleets, high-performance vehicles, and hybrid powertrains alike, this Coolant Hose Assembly withstands the harshest operating conditions while maintaining leak-free coolant circulation for over 150,000 miles of service.

1. Material Innovation & Structural Integrity

The Anti-aging Coolant Hose Assembly features a proprietary four-layer construction:

Inner Liner: High-density EPDM rubber with 45% carbon black reinforcement, resisting glycol degradation and electrolytic corrosion

Thermal Barrier: Silicone-impregnated fabric reflecting radiant heat from exhaust manifolds

Outer Jacket: Weather-resistant FKM compound with UV stabilizers, maintaining flexibility from -40°C to +180°C

This architecture enables the Coolant Hose Assembly to endure 25+ bar pressure spikes in turbocharged engines while preventing the 0.2mm/year wall thinning common in standard hoses.

2. Anti-aging Technology Breakthroughs

Our Anti-aging Coolant Hose Assembly integrates three core innovations to combat degradation:

Hydrolysis Resistance: Specialized polymer chains prevent coolant permeation-induced swelling.

Ozone Shield: Triple-layer antioxidant additives eliminate surface cracking in high-ozone environments

Dynamic Flex Reinforcement: Spiral-wound stainless steel wire prevents kinking during 15mm+ engine movement

3. Performance Validation

Rigorous testing certifies the Coolant Hose Assembly's capabilities:

Thermal Cycling: 50,000 cycles between -40°C and 150°C (SAE J20 R3 compliant)

Abrasion Resistance: 2mm wear depth after 10,000km simulated gravel road vibration

Chemical Immersion: 0% tensile strength loss after 30-day exposure to biodiesel/coolant mixtures

4. Application-Specific Engineering

Commercial Vehicles:

The Anti-aging Coolant Hose Assembly features 3-ply steel wire reinforcement for mining trucks enduring 60°C coolant temp differentials

Hybrid/Electric Vehicles:

Electrically insulated variants prevent stray current corrosion in battery-adjacent installations

Marine Engines:

Biofilm-resistant inner surface inhibits microbial growth in high-humidity environments

5. Economic & Operational Benefits

By integrating the Coolant Hose Assembly, operators achieve:

Fuel Efficiency Gains: Maintains optimal coolant flow to reduce engine warm-up time by 35%

Downtime Reduction: Quick-connect fittings enable 15-minute replacements without coolant drainage

6. Sustainability Leadership

The Coolant Hose Assembly supports eco-conscious operations:

30% Post-industrial recycled FKM content

REACH/RoHS-compliant formulations eliminating PAH/PVC content

Closed-loop recycling program recovering 85% of end-of-life hose materials

7. Future-Ready Design

Next-gen Anti-aging Coolant Hose Assembly prototypes integrate:

From scorching desert highways to arctic tundra operations, our Coolant Hose Assembly delivers uncompromised thermal management – proven to reduce engine-related breakdowns by 62% in fleet trials while cutting annual cooling system maintenance costs by $1,200 per vehicle. By combining molecular-level anti-aging science with industrial-grade durability, this innovation sets new benchmarks in engine protection and operational efficiency.