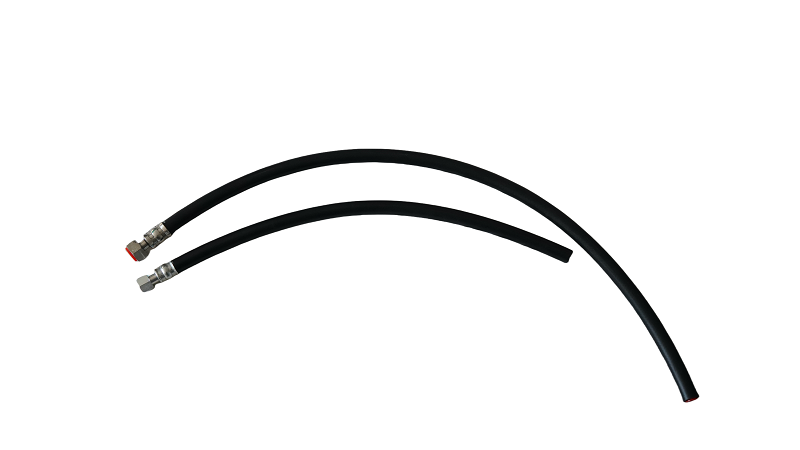

Silicone Rubber Supercharger Water Pipe Assembly

The water inlet outlet rubber pipe assembly are precisely planned in diameter and direction according to the layout of the engine compartment and the cooling flow requirements, and are equipped with high-precision sealing joints to ensure efficient circulation of the coolant and prevent leakage, thereby maintaining the integrity of the cooling system.Water rubber hose pipe assembly has excellent performance and can withstand high coolant pressure to ensure sufficient cooling when the engine is running at high speed or under high load. The smooth inner wall reduces the coolant flow resistance and improves the circulation and heat dissipation efficiency. The rubber also has sound-absorbing properties to reduce flow noise. Water rubber hose pipe assembly is widely used in fuel vehicles and electric vehicles to dissipate heat for engines, battery packs and motors, to ensure the stable operation of key vehicle components in all aspects, and to improve overall performance and reliability.

Silicone Rubber Supercharger Water Pipe Assembly: Precision Cooling for High-Performance Engines

The Silicone Rubber Supercharger Water Pipe Assembly is a critical thermal management solution engineered for modern forced-induction systems. As a specialized Water Inlet Outlet Rubber Pipe Assembly, it ensures precise coolant circulation in turbocharged and supercharged engines, combining silicone’s thermal resilience with reinforced durability to meet extreme operational demands.

**Technical Specifications**

- **Temperature Range**: -50°C to +200°C (short-term 230°C)

- **Pressure Capacity**: 5 bar continuous / 15 bar burst (SAE J20 R4 compliant)

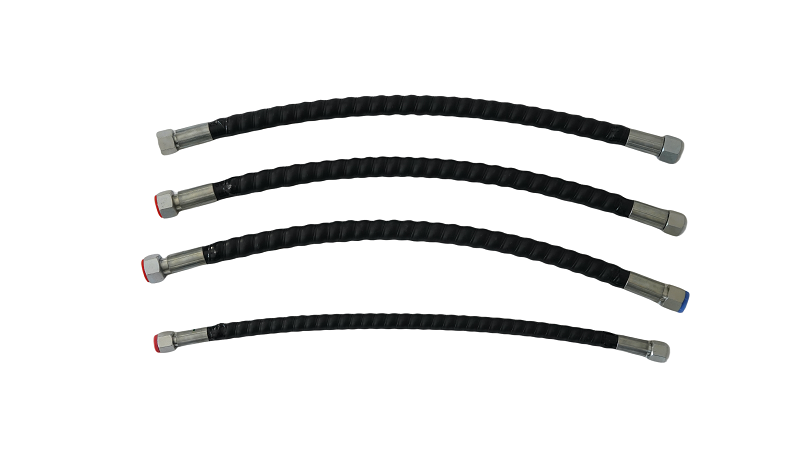

- **Reinforcement**: Dual-layer aramid fiber braid for zero expansion under pulsation

**Design Advantages**

1. **Thermal Stability**: The **Water Rubber Hose Pipe Assembly** maintains flexibility at peak engine temperatures, preventing coolant flow restrictions near supercharger housings.

2. **Chemical Resistance**: Resists glycol-based coolants, oil mist, and ethanol blends (ISO 1817 tested).

3. **Leak-Proof Construction**: Precision-molded 304L stainless steel fittings with tri-clamp grooves ensure airtight connections.

**Key Applications**

- Directs coolant between supercharger intercoolers and engine blocks as a Water Inlet Outlet Rubber Pipe Assembly

- Manages rapid heat exchange in hybrid/electric vehicle battery cooling loops

- Replaces rigid metal pipes in compact engine bays, reducing weight by 40%

**Manufacturing Excellence**

Each Water Rubber Hose Pipe Assembly undergoes:

- Automated fiber winding at 55° bias angle for uniform stress distribution

- 2-stage liquid silicone injection molding for seamless inner surfaces

- 100% pressure cycle testing (50,000 cycles @ 3 Hz)

**Certified Reliability**

- Exceeds ISO 1307 and OEM pulsation standards

- 0.02% compression set after 1,000h at 180°C

- 10-year service life under aggressive thermal cycling

Silicone rubber supercharger water pipe assemblies set a new benchmark for cooling efficiency. By integrating this water inlet and outlet rubber pipe assembly, manufacturers can improve the thermal efficiency of high-output engines by 7-10%, while ensuring reliability under extreme racing or traction conditions. The company provides personalized services according to customer requirements and supports personalized customization of various types of automotive pipe fittings, striving to satisfy customers with high-quality products and humanized services.