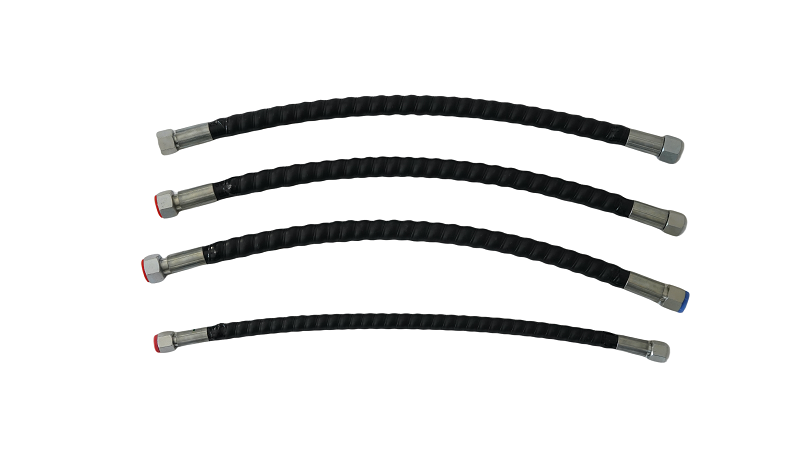

Automobile Special Anti-aging Brake Hose Assembly

The aging-resistant brake pipe assembly for automobiles has a reasonable structural design. It is usually composed of an inner tube, a reinforcement layer and an outer protective layer. It can perfectly adapt to the erosion of brake oil, ensure that the brake oil will not leak during the transmission process, and maintain the stable operation of the brake system. In terms of material, the outer protective layer is a highlight, using a highly aging-resistant special rubber material. This material can effectively resist the invasion of harsh environmental factors such as ultraviolet rays, high temperature, and humidity. Even if the vehicle is exposed to the outdoors for a long time, experiencing wind, sun, and rain, the brake pipe is not prone to aging, cracking, and other problems, which greatly extends the service life and reduces safety hazards caused by aging.

Automobile Special Anti-Aging Hose Assembly: Precision Engineering for Braking Safety

In the critical realm of automotive braking systems, where safety is paramount, the Automobile special anti-aging hose assembly—and its core component, the Brake pipe—serves as a lifeline for reliable vehicle operation. Brake pipe designed to withstand extreme pressures and environmental challenges, this assembly ensures instantaneous brake response and long-term durability, directly safeguarding driver and passenger safety.

Structural Integrity: Layered Defense for Optimal Performance

At the heart of the brake pipe lies its multi-layered architecture. The innermost layer is a precision-engineered Brake pipe crafted from advanced oil-resistant polymers such as fluorocarbon or nitrile rubber (NBR). These materials undergo rigorous formulation and testing to achieve a densely packed molecular structure, effectively blocking brake fluid permeation. Even under prolonged exposure to corrosive glycol-based or DOT-compliant fluids, this layer prevents swelling, degradation, or micro-leaks—critical for avoiding brake failure caused by fluid loss.

Reinforcement Layer: Strength Under Pressure

The middle reinforcement layer is a masterclass in material science. For steel wire-braided variants, high-tensile stainless steel strands undergo specialized heat treatment to enhance strength (exceeding 2,000 MPa) and fatigue resistance. This design prevents radial expansion of the Brake pipe, ensuring zero deformation and preserving brake pedal feedback accuracy.

Performance Beyond Standards

Certified to ISO 11425, SAE J1401, and OEM specifications, the Brake pipe operates flawlessly across a temperature range of -40°C to 150°C. Brake pipe outer cover, fortified with ozone- and UV-resistant EPDM rubber, shields against abrasion, engine bay heat, and road salt corrosion. Advanced versions integrate anti-abrasion textile sleeves for added protection in high-friction zones.

Safety Through Innovation

The Automobile special anti-aging hose assembly is not just a component—it’s a safety system. By eliminating fluid permeation (tested to <0.1 g/m² per 24h under SAE J1401), it prevents brake fade during downhill driving or heavy towing. Brake pipe burst pressure rating, exceeding 70 MPa, ensures reliability even in catastrophic scenarios. Automotive manufacturers rely on this assembly for hybrid/electric vehicles, where regenerative braking demands precise hydraulic coordination.

In summary, the Automobile special anti-aging hose assembly and its Brake pipe redefine braking system excellence. Through layered material innovation, precision engineering, and relentless testing, this assembly delivers uncompromising safety, durability, and performance—cornerstones of modern automotive design.