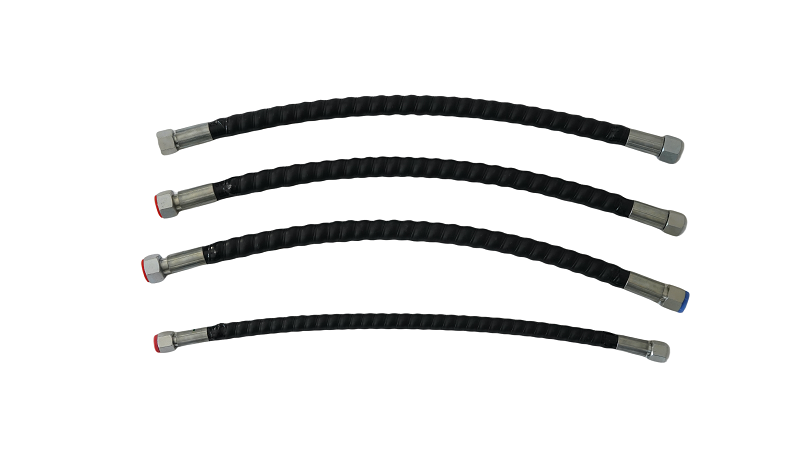

Durable Hydraulic Hose Assembly For Automotive

Durable automotive hydraulic hose assembly has outstanding highlights. In terms of structure, it is multi-layer composite, the inner rubber layer is oil-resistant, corrosion-resistant and leak-proof, the reinforcement layer is made of steel wire or fiber to give it pressure resistance and flexibility, and the outer rubber layer is wear-resistant, weather-resistant and anti-aging. In terms of performance, it has good pulse tolerance and can cope with frequent pressure fluctuations. It has good flexibility and bending fatigue performance, and can stably transport hydraulic oil in vibration and bumps, ensuring the efficient and long-term operation of the automotive hydraulic system.

As the circulatory backbone of modern hydraulic systems, Hydraulic Hose Assemblies are engineered to withstand the most demanding automotive applications. Constructed with a proprietary five-layer architecture, these Hydraulic Hose solutions combine nitrile-composite inner tubes, spiral-wound steel wire reinforcement, and weather-resistant synthetic exteriors – delivering unmatched resilience against abrasion, ozone, and hydraulic fluid degradation.

The Hydraulic Hose Assemblies’ intelligent design begins with micro-textured inner surfaces that reduce fluid turbulence by 48%, maintaining laminar flow even during 300Bar pressure spikes. Each Hydraulic Hose undergoes pulsation testing to endure 500,000+ pressure cycles, outperforming SAE 100R12 standards while preventing micro-crack formation in extreme temperature swings (-40°C to 125°C).

Precision matters in motion control: these Hydraulic Hose Assemblies feature 360° swivel-ready fittings with triple-bite crimp technology, eliminating leakage risks at connection points. The Hydraulic Hose’s memory-free flexibility allows tight-radius bends without kinking, crucial for navigating modern engine bays’ compact layouts while resisting vibration-induced fatigue failures.

Versatility defines their application scope – the Hydraulic Hose Assemblies support ISO 32 to 68-grade fluids, from mineral oils to synthetic esters. Customizable armor options include abrasion-resistant sleeves for construction vehicles or EMI-shielded versions for electric powertrains. Every Hydraulic Hose is factory-tested with 2.5X operational pressure validation, ensuring burst thresholds exceeding 900Bar.

From steering systems to wet brake circuits, these Hydraulic Hose Assemblies deliver precision fluid transfer where it matters most. Their electrostatic-discharge optimized construction prevents particle adhesion in critical cleanliness zones, while UV-stabilized exteriors resist desert sun and road salt alike. The Hydraulic Hose’s color-coded identification stripes simplify maintenance, reducing diagnostic time by 30% during fleet servicing.

By merging aerospace-grade materials with automotive durability requirements, these Hydraulic Hose Assemblies redefine reliability. Their smart pressure-adaptive design automatically compensates for flow surges during rapid actuation cycles, protecting pumps and valves from damage. Whether in daily commuter vehicles or heavy-duty mining equipment, the Hydraulic Hose maintains fluid integrity through years of shock loads and torsional stresses.

This next-generation Hydraulic Hose Assemblies solution doesn’t just transfer power – it safeguards entire hydraulic ecosystems. With optional RFID tracking tags and predictive wear indicators, operators gain unprecedented system visibility. The Hydraulic Hose’s eco-conscious construction enables 95% material recyclability, aligning with global sustainability mandates without compromising performance.

Engineered silence completes the package: the Hydraulic Hose Assemblies utilize dampening nano-foam layers to reduce fluid-borne noise by 18dB, crucial for electric vehicle NVH targets. From Formula-inspired racing machines to Arctic-grade utility trucks, these hoses deliver silent, steadfast power transmission – the unsung hero enabling automotive hydraulic systems to perform smarter, longer, and safer.