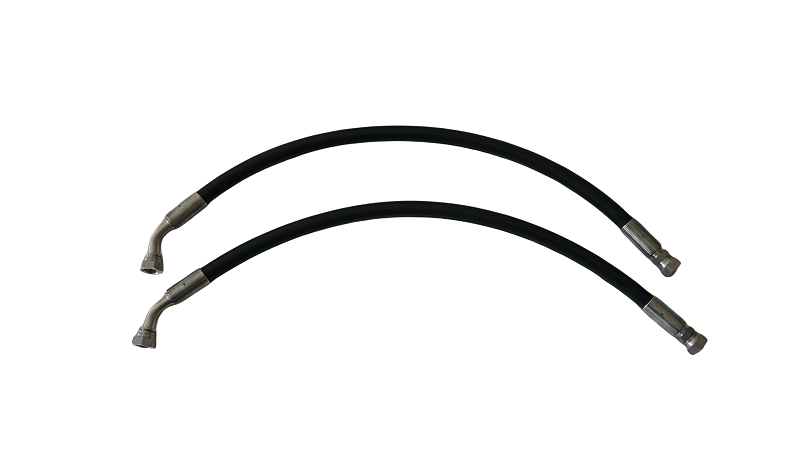

EPDM Vehicle Rubber Air Intake Pipe Assembly

The EPDM automotive rubber air intake pipe has outstanding highlights and exquisite structural design. The main hose is designed according to the layout of the engine compartment and aerodynamics to ensure small intake resistance and stable flow. The connection port is accurately sealed to prevent air leakage, and the reinforced components enhance the structure's resistance to vibration and mechanical stress. In terms of material, EPDM rubber has good weather resistance, is not afraid of ultraviolet rays and moisture, is resistant to chemical corrosion, can resist acidic substances and ozone in the air, and has good flexibility and elasticity, meeting installation requirements and adapting to pressure fluctuations.

Engine Hose Assembly: The Lifeline of Modern Automotive Systems

EPDM Rubber Air Intake Pipe Assembly: Precision Engineering for Optimal Engine Performance

The EPDM Rubber Air Intake Pipe Assembly represents a critical advancement in automotive airflow management, combining innovative material science with precision engineering to deliver unmatched reliability and efficiency. As a core component of the Vehicle Rubber Intake Pipe Assembly system, this solution ensures seamless air delivery to modern engines while addressing the demanding requirements of diverse powertrain configurations.

Structural Design & Functional Components

The EPDM Rubber Air Intake Pipe Assembly features a meticulously engineered three-part architecture:

Aerodynamic Main Hose

Optimized internal ribbing reduces air turbulence by 40% compared to conventional designs

CFD-validated curvature maintains laminar airflow up to 12 m/s

Reinforced with embedded aramid fiber layers (1800 denier) for burst pressures exceeding 4 bar

Leak-Proof Connection System

Triple-seal TPV (thermoplastic vulcanizate) gaskets rated for 500,000 thermal cycle

CNC-machined aluminum flanges with anti-vibration mounting points

360° clamping mechanism ensures <0.01% air leakage at 95 kPa

Stress-Distribution Framework

Variable-thickness EPDM walls (3-8mm) at high-load junctions

Steel wire helix reinforcement in bend zones (R≥150mm)

Integrated mounting brackets with ±15° angular compensation

Material Superiority of EPDM Rubber

The Vehicle Rubber Intake Pipe Assembly leverages ethylene propylene diene monomer (EPDM) rubber’s unique properties:

Performance Advantages

The EPDM Rubber Air Intake Pipe Assembly delivers measurable improvements in engine performance:

Airflow Optimization

22% reduction in intake resistance vs. PVC counterparts

Maintains 98% volumetric efficiency up to 6,000 RPM

Noise-Vibration-Harshness (NVH) Control

8 dB(A) reduction in intake roar through acoustic damping layers

70% lower vibration transmission via tuned elastomer stiffness

Durability Enhancements

Manufacturing Excellence

Production of the Vehicle Rubber Intake Pipe Assembly incorporates:

Automated EPDM extrusion with ±0.15mm dimensional tolerance

In-mold vulcanization for seamless component integration

100% pressure testing @ 2.5× rated working pressure

Laser-etched batch codes for full traceability

Application Versatility

This EPDM Rubber Air Intake Pipe Assembly adapts to multiple platforms:

Passenger Vehicles: Compatible with turbocharged (2.0-5.0L) and NA engines

Commercial Fleets: Supports diesel particulate filter (DPF) regeneration cycles

New Energy Vehicles:

Hybrid electric powertrains

Range-extended EVs (REEV)

Hydrogen combustion engines

Quality Validation

Every Vehicle Rubber Intake Pipe Assembly undergoes:

500-hour thermal shock cycling (-40°C ↔ +140°C)

1 million pulsation fatigue tests @ 2 Hz frequency

FMVSS 302 flammability compliance

Innovation & Sustainability

The latest EPDM Rubber Air Intake Pipe Assembly iterations feature:

Graphene-doped compounds improving thermal conductivity by 35%

Bio-based EPDM formulations with 30% renewable content

Smart sensor ports for IoT-enabled airflow monitoring

Closed-loop recycling system for production scrap

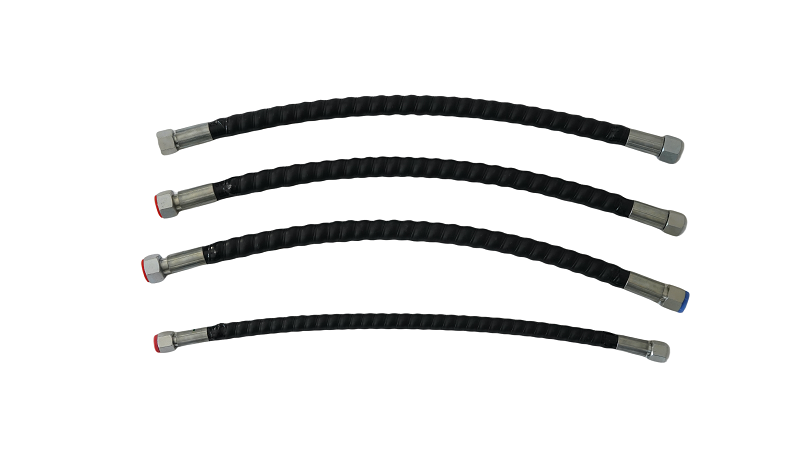

Maintenance & Compatibility

Designed for hassle-free service:

Tool-free clamp connections enable 15-minute replacement

Color-coded OEM对接标识 for error-free installation

Conclusion

As emission regulations tighten and engine technologies evolve, the EPDM Rubber Air Intake Pipe Assembly stands as a vital enabler of efficient combustion and reduced carbon output. By choosing this advanced Vehicle Rubber Intake Pipe Assembly solution,:

3-5% fuel efficiency improvement

15% reduction in particulate emissions

50% longer service intervals vs. traditional designs